Colchester Student 1800 Guide

P colchester 1800 lathe manual call of the wild student study guide answers mob rats 4 book series komatsu wa270 3 wa270pt 3 wheel loader service.

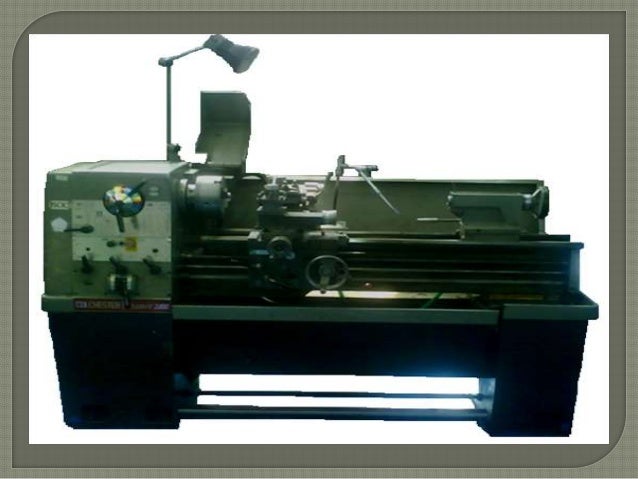

Machine Summary Machine Ref: 823 Manufacturer: Colchester Model: Student 1800 Description: Lathe (907) Electrics: 415 Volt 3 phase Year: Price: £0.00 Equipment and Features 3 Jaw Chuck Gap Bed Face Plate Lo-vo Light Dual Dials Chuck Guard Bed Stop. Machine Specification Speeds 28 - 1800 rpm x 16. Centre height: 6.5' (165mm ) Between centres: 40' (1016mm ) Swing over bed:13.25' (335mm ) Swing in gap: 19' (480mm) Spindle Nose 4' D.1 Camlock Spindle Bore Dia: 1.625' (40mm) Tailstock 3 Morse Taper. Weight 1850 lb (840kg) Motor 3 HP 415 volt 3 phase.

Im not familiar with those lathes, but in general you will have a set of levers usually located under the chuck speed selector for controlling feed/lead rates. These are labelled by a data plate on the lathe which will give you information on feed per revolution.

Also should be another lever for direction of feed, and yet another to turn the feed system on (feed screw) or turn the screw cutting system on (lead screw) Just a word of caution. Be careful not to engage the lead screw with a high chuck speed! It can travel very fast and crash into the job or more serious. General info. Hopefully of some use! Dare say you mean the longitudonal and cross feed rates, surfacing.

They are linked to the gearbox setup so if set on 1mm pitch it will be finer than say 5mm pitch. Same as any 600 Group lathe including some parts ie Harrison. There should be a chart some where, that lathe should cut more tpi than listed on headstock. What usually happens though the feed rate is about half or less than screwcutting chart seen below speed adjustment knob.

The main difference to Harrisons is the apron, Colchester handles on the right in the way of cross slide wheel. Screwcutting lever top? Choose power feed selector bottom left? You would tell by screwcutting half nuts and having a wider pitch per rev. Both cant be engaged together, safety feature. Just underneath cross slide handle is the longitudonal or cross feed selector, neutral mid way and may have to revolve spindle for it to drop in.

Just make sure lead screw is rotating. If not a gearbox selector hasnt dropped in, rotate spindle by hand. Three levers A to Z plus bottom numbered selector, could be any one. Direction change of lead screw is below speed adjustment on left. Its the one i was referring to earlier as well, same as newer Harrisons from 65 onwards, share same parts across the range to the Triumpth and M400.

Lever to left of speed selector is lead screw direction change and neutral. Top left lever on carriage is screwcutting half nut and cant be engaged whilst power feed bottom left lever is in position and vice versa. Feed rates are altered with the three levers and H box selector at bottom. This also does imperial and metric without faffing about with change wheels, just dial it in. Usually leave mine set on AR3W which is 1mm pitch if screwcutting.

Colchester Student 1800 Manual Download

On longitudonal power feed that leaves a superb finish no cylindrical crevices on any material. Can go to AR7W think is 1.5+ pitch before any turn marks set on X feed are evident as an example.