Fanuc Controls Manual Guide Mf M6

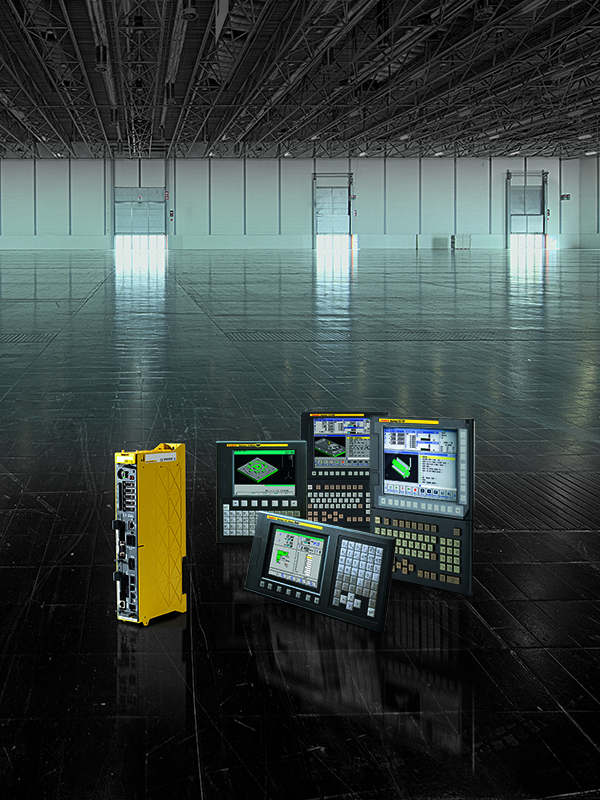

MANUAL GUIDE i a user-friendly conversational programming platform that makes it easy to perform create part programs right on the shop floor. The innovative programming enables development from a drawing to a production part in a very short time. Thanks to MANUAL GUIDE i, FANUC CNCs can be programmed very easily and quickly, for turning, milling and compound machining. Self-explanatory menus and graphic simulations guide the user through the programming, producing highly efficient results even for complex machining processes.

MANUAL GUIDE i software is based on the ISO code format and has an ergonomic CNC user interface for programming cycles. It uses a graphical user interface with user-friendly icons which allow you to interactively create part programs in just a few steps.

G-Code G68 and G69 Coordinate System Rotation for CNC Machinists. [ Easy Tutorial & Guide ]. Is Manual Machining Faster than CNC for Simple Parts? Numbers an encouragement to quantitative thinking,fanuc controls manual guide mf m6,2016 thor motor coach quantum class c ws31,honda shadow spirit 750 2015 owner manual,1989 daihatsu feroza f300 service repair manual,chrysler sebring 2006 repair service manual,workshop manual for.

All of the relevant information is displayed on one CNC screen. Having to constantly change between screens is thus avoided as is the risk of getting lost in the numerous pop-up screens. Features:. Operator friendly programming environment. Advanced Cycle Machining (Turning and Milling). Powerful profile calculation. Seamless environment switching.

Fanuc Controls Manual Guide Mf M6500i

Tool management function. Set-up guidance. Residual cutting. Background machining simulation Need some help getting started with MANUAL GUIDE i? You can view some webinars, hosted by Modern Machine Shop, that were designed to be quick reference guides to get you up and running in no time.